Heating a meat factory using TM Teplov

Meat processing infrared heating: the best solution for reliability and efficiency

Infrared (IR) heaters TeploV - a universal solution for heating any kind of objects. Over the 15 years of their existence on the market, they have proven their effectiveness in the conditions of shopping and entertainment centers, banks, production shops, warehouses, apartments, cottages, houses, etc. Recently, our company has created a meat processing plant heating system based on infrared heaters. Such equipment will allow to maintain a comfortable temperature in the premises of the workshops with minimal energy costs..

Features of infrared heaters of the P series

Heating for the meat processing plant is built on infrared heaters from the industrial series (models P2000 and P3000). They have proven themselves in work in large areas and non-standard rooms. This equipment during operation demonstrates indicators inaccessible to classic heating systems. One heater is capable:

- provide a temperature of + 20 С indoors 20 m2 at an ambient temperature of -26 0С;

- maintain a comfortable temperature in the workshop of a meat factory with an area of 40 m2 during the off-season (up to -4 0С);

- work effectively as additional heating in rooms the area of which does not exceed 40 м2.

Our infrared heating for a meat processing plant can be installed in workshops with a height of 3 to 15 meters. Depending on the specifics of each room, it is envisaged to fix the heaters either on the lighting support structures or on cables with separate brackets.

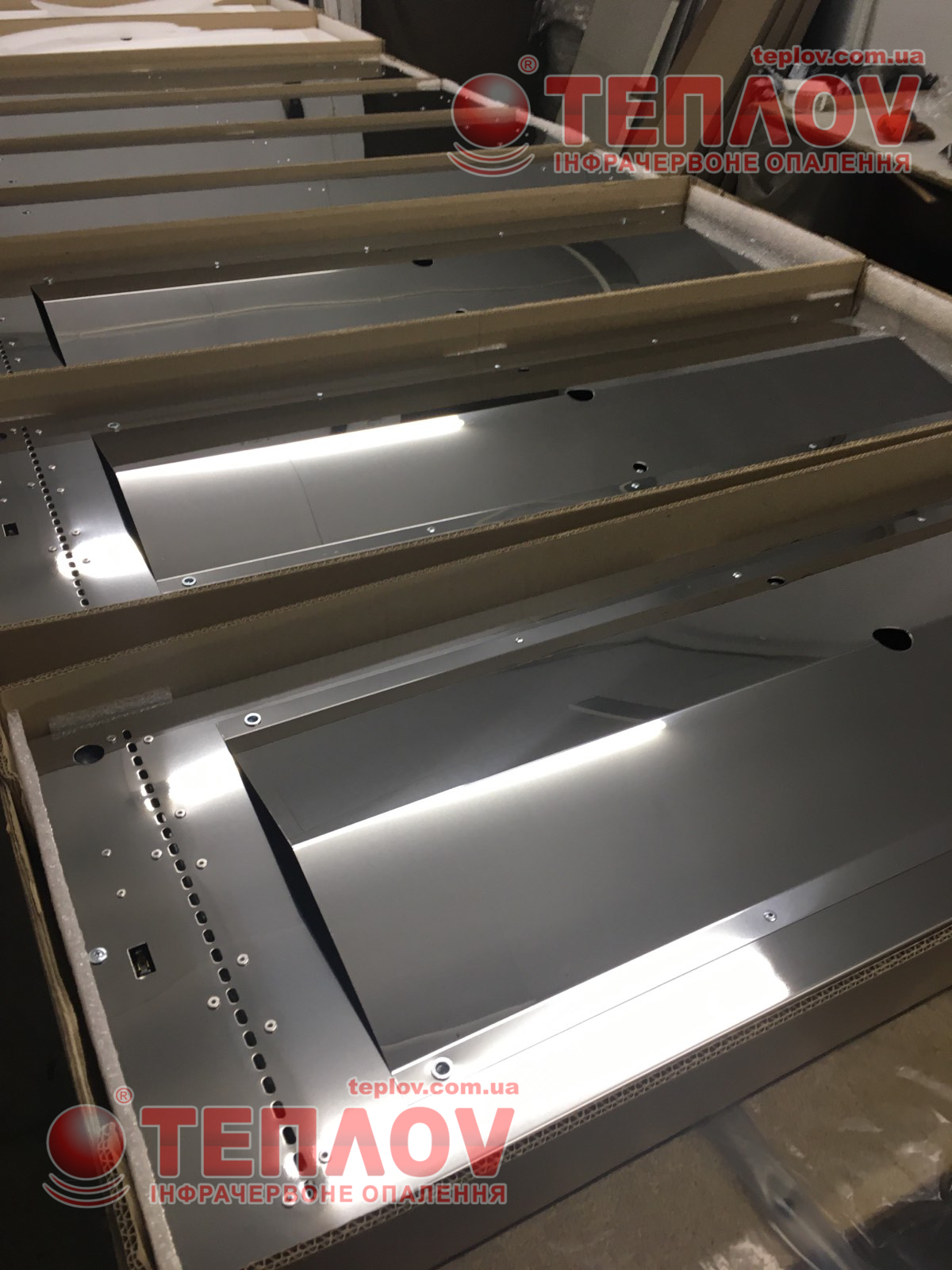

We have modified the equipment to meet customer requirements and the specifics of the meat processing plant. In particular, heaters are built into stainless steel enclosures. Such a solution will provide reliable protection of the heating equipment of the meat processing plant from corrosion due to regular exposure to high humidity and significantly extend their service life. The equipment is covered by a 10-year warranty, although we are confident that it will work effectively for at least 25 years.

The benefits of infrared heating

The increased popularity and demand for infrared heaters among individuals, industrial facilities and meat processing plants, in particular, has contributed to the significant advantages of this equipment:

- High heating rate. For a person to become warm from an oil radiator, it takes about 30 minutes of time. In convectors, this process is faster, but the difficulty is that heated air is lighter than cold air, so it will rise. A person will feel heat only after the air masses are mixed. Infrared heating of the meat processing plant begins to heat personnel already 27 seconds after switching on.

- Direct heating. Other types of heaters initially heat the air, and already it transfers heat to walls, furniture, people and other objects in the room. The IR heater already heats consumers from the very beginning. That is, energy will be completely spent on creating comfortable working conditions for staff.

- Profitability. IR heaters do not heat the entire room, but act locally. To warm a room with an area of 20 m2, an oil device will require 1500-2000 watts, and infrared - about 700 watts. Low power consumption significantly reduces payback periods. Yes, the price of infrared heating of a meat factory initially seems rather big, but the system will pay off in a maximum of 3-4 years.

The advantages of infrared heating include quiet operation, the absence of convection processes, and a long service life.

We are sure that everyone who still decides to buy ceiling heaters both for a meat processing plant and for other objects from TeploV will be satisfied with the efficiency and reliability of the equipment, and with cooperation with our company as a whole.